Designing and Delivering a High-Precision Dryer Room Lab within an Active Pharmaceutical Facility

Ardmac was appointed to design and deliver critical infrastructure within a live manufacturing environment

Client: Clarochem

Location: Dublin, Ireland

Project Size: 32 sq/m plus support rooms

Duration:

Introduction

Ardmac is trusted by leading pharmaceutical manufacturers for delivering complex projects in highly regulated environments. Our expertise in OSM, specialist fitout and structural installation was central to the successful upgrade of our client’s Ireland facility, where precision, safety, and collaboration were paramount.

The client required an expansion of its operational capacity without interrupting production. Ardmac was appointed to design and deliver critical infrastructure within a live manufacturing environment – a challenge that demanded meticulous planning and flawless execution.

Scope of Works and Execution

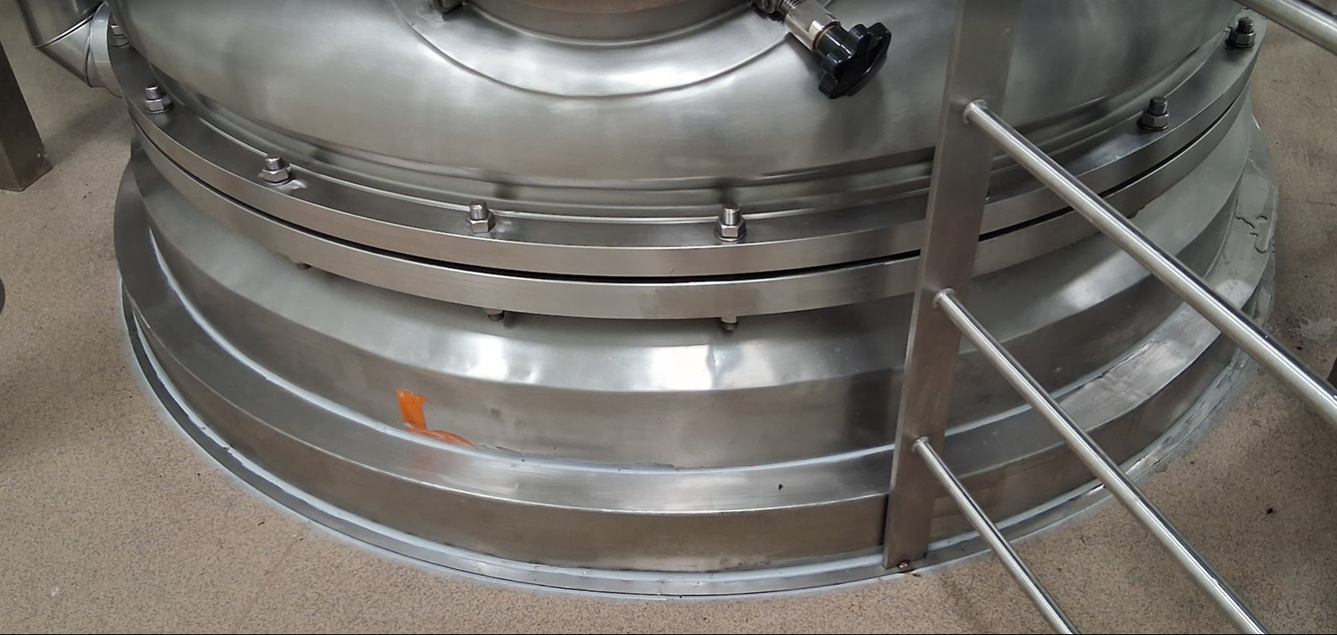

The project involved constructing a new dryer room, installing a mezzanine structure complete with equipment, and building a dedicated platform for the Dehumidification Unit (DHU) and its associated plant. These elements were essential to supporting our client’s process-critical operations and were delivered to the highest standards of quality and compliance.

A dryer room (sometimes called a drying room) is a controlled environment used to remove moisture from materials during drug manufacturing. It plays a critical role in ensuring product stability, quality, and compliance with Good Manufacturing Practices (GMP).

Working within an active pharmaceutical facility meant every step had to be carefully coordinated. Ardmac implemented a joint permit-to-work system with the client to maintain rigorous safety governance. This process was also made more efficient through the adoption of OSM within the prefabrication process.

Daily coordination meetings and real-time issue tracking ensured smooth progress despite overlapping scopes with the client’s installation and M&E teams. Segregated walkways, controlled delivery schedules, and exclusion zones were introduced to protect both personnel and production integrity.

The result: zero major safety incidents and uninterrupted client operations.

Innovation

Prefabrication through OSM (Off Site Manufacturing) was a key innovation on this project, with sections of the mezzanine manufactured off-site to reduce on-site time and enhance safety. Ardmac also developed an integrated programme aligning construction activities with the client’s operational constraints, ensuring seamless interface management.

Sustainability measures included modular construction to minimise waste, recycling protocols, and the use of local supply chain partners to reduce transport emissions.

Outcome

The project was delivered on time and within budget, reinforcing Ardmac’s reputation for excellence in pharmaceutical environments. Through collaboration, innovation, and unwavering attention to safety, we helped the client achieve its goal of increased production capacity without compromising ongoing operations.

“This project exemplified coordination and adaptability in a live operational setting. By integrating all contractors into our RAMS and permit systems, we maintained safety and progress throughout. It’s rewarding to deliver a solution that supports our client’s ongoing operations.” – David Higgins, Head of OSM, Ardmac

Learn more about Ardmac OSM cleanrooms by visiting ardmac.com/building-offsite.