Any business that has chalked up nearly half a century of operation will have demonstrated an ability to move with the times and this has certainly been the case for Ardmac. The County Dublin-based company’s progressive approach has not only seen them continue to flourish commercially but has also enabled the business to achieve significant industry recognition, as was underlined when Ardmac recently secured the silver accolade for BIM Excellence at the Irish Construction Excellence Awards.

“Winning awards of this nature provides external verification of our approach, as they recognise the dedication and innovation that we strive for and our ability to overcome challenges,” explains Michael Quinn, Managing Director. “They also show that we’re doing things correctly and are moving in the right direction.

“There’s no doubt that the latest award helps to showcase what we can do, putting us out there in the public domain and underlining our capabilities. It helps us to distinguish ourselves further from the competition.”.

“We’ve always been a forward-thinking company, keen to explore emerging technologies and try new ways of doing things. As part of this strategy, we’ve been a long-time supporter of BIM and have been on our own digitalisation journey for over 15 years.”

One individual who has played a key role in Ardmac’s digital journey recently and was integral to the subsequent award success is Fabrizio Giargeri, BIM Manager, who was quick to pay tribute to the company’s firm foundations. “When I joined the company three years ago, there was already a deep understanding of what BIM is and how it works. This gave me an excellent platform on which to push forward.

“We have since developed new technologies and processes as part of the digitalisation 2.0 process. This relates to all the innovations that are growing in influence within the market, such as AI and the Internet of Things, which we are striving to implement into our approach.

“It is essential as projects grow more complex, with clients seeking greater clarity, more data, and deeper insights. Gone are the days when their sole focus was on constructing and occupying the building. Now, they want a digital twin model. The goal is to provide all the knowledge and information they need from a facilities maintenance perspective to ensure the building operates optimally throughout its lifespan.”

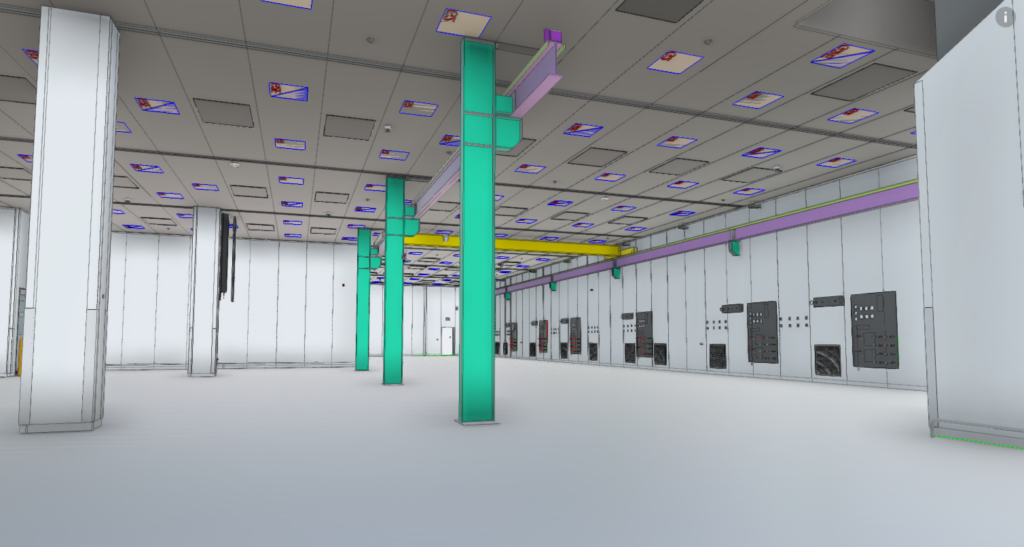

This ability to give clients the level of data they require really came to the fore on the project on which Ardmac’s BIM Excellence Award was based. “Everything had to be modelled and analysed in the digital environment. The client was then able to navigate the design BIM Model and interact with it; changing the colours, the lighting, or the furniture. This is the whole purpose of bringing the BIM information through and making the process much more accessible.”

Ardmac’s move into digital construction reflects the progression the company has made since their inception in 1977. Ardmac started life as a commercial fit-out contractor before evolving into a specialist in cleanrooms, the demand for which has grown considerably with the emergence of high-tech sectors such as life sciences, medical device technologies, data centres and EV battery facilities that require strictly controlled environments. As well as their cleanroom projects, which make up the lion’s share of its workload, Ardmac still carry out commercial office refurbs and fit outs, predominately in the Dublin region.

As their reputation has grown, so has the number of countries in which Ardmac operates. Following their first venture outside of Ireland, an office in Manchester was created in 1987. The company now has a presence in 12 different countries, as they continue to steadily increase their influence across Europe. In 2017, Ardmac added offices in Switzerland and Denmark, and more recently they have moved into Finland and Germany.

“Typically, we move into some new jurisdiction each year, much of which stems from our existing client base and meeting their needs as they grow,” highlights Michael. “Customers will often come to us when moving into a different country, rather than having to try and find somebody new to deliver their cleanroom facilities. We believe that this is due to the trust we have built with our clients over the years which in turn is why around 85 per cent of our workload is repeat business.”

This level of continuity is only possible due to the high standards Ardmac adheres to and the consistency they can provide, all based upon the solid infrastructure they have built up over the years. During the history of Ardmac, they’ve formed partnerships with several like-minded companies across the globe that have helped them to maintain forward momentum.

“We have a number of different partnerships in place including with US companies, such as Performance Contracting Inc. and Germfree, and Cental, which has been part of the Ardmac Group since 2022.”

“The growing demand for modular construction has stemmed from the benefits it brings to the marketplace and the fact that it is able to overcome many of the challenges that the industry is facing at the moment. We have gotten to a point where we are completing in excess of 80% of the work elements off-site on a consistent basis. Once you’re in that sort of range, that’s where you’re really recognising the benefits that a modular approach can bring. It also dovetails nicely with the requirements of BIM and the amount of data it needs.”

With a team of over 500 staff members, the focus for Ardmac is not only their IT systems and modular processes. Their priority is always health and safety. “Our guiding principles were established a long time ago and they are something we continuously live by,” highlights Michael. “Putting safety first is key to everything we do. What’s important is making sure that everyone working for us gets home to their families. Consequently, we have a very strong health and safety record and at one point we reached 7million working hours without an incident. The high safety standards we have in place are driven from the very top, from the C-Suite level and across all areas of the organisation.

“Our success has come from the culture we have developed and our ability to normalise conversations around health and safety, which was often viewed as a difficult topic for discussion. By taking a less formal approach, people are more willing to talk about safety rather than feeling like they’re being controlled and micro-managed. By making the subject more relatable people react much better.”

As well as their excellent safety performance, another of Ardmac’s USPs is their technical expertise, which is vital as they operate in the high-tech sectors. Having such strong in-house technical knowledge allows Ardmac to sit with the client and very quickly understand their needs and in turn to come up with the optimum solution.

“We believe there aren’t many other companies that are able to provide what we can, in terms of our turnkey, design and build delivery of controlled environments of all sizes. Our success in this area is built on the technical expertise and experience of our design and construction teams developed over the last 40 years.

“We have an in-house design and engineering team of over 60 people, which is comprised of architectural technicians and all the various engineering disciplines. In terms of our BIM expertise, it’s something we’ve put a great deal of time and effort into. We believe we are currently performing at the highest level in this area.

“Investment has been crucial to underpinning our approach and we have a dedicated digital construction working group that’s driving the digitalisation agenda company wide. The work Fabrizio and the rest of the team carries out was a major factor in our BIM Excellence Award success.

“When Fabrizio joined the company, we set out a five-year road map around BIM, which has been aimed at making sure that we stayed ahead of the curve. This has proven to be a very successful approach.”

Modern modular construction is a far cry from the old stereotypes associated with prefabricated buildings. The quality of modular buildings now lends itself much better to permanent building and is comparable, if not superior in many regards, to traditional construction.

“Whether it’s with regards to labour force productivity, quality control, management, or speed of delivery, these are all elements that can be enhanced through the use of modular solutions.”

To maximise the potential that modular holds, Ardmac have 10,000 sq m of manufacturing space available at the Cental Engineering facility in Carlow on an 18-acre site with the ability to increase production through other supply chain as and when required.

“We have seen an increasing level of interest in modular solutions across various sectors over the last number of years and most recently in the data centre space. We’re currently involved in our first full-building modular project in this area. The likes of AI and quantum computing require a massive amount of data processing power, so it’s hopefully going to be a growth area for the foreseeable future, and modular can be part of this sector’s solution.

“From our own point of view, we’re extending our reach in terms of where we can provide modular solutions to, particularly in more remote locations. We’ve recently shipped modules to Africa for a life sciences client operating a vaccine production facility. We’re keen to build upon that further and make the most of the flexibility that modular can provide. It’s going to be a key target area for us.”

By always keeping one eye on what the future might bring, Ardmac are well prepared to embrace the next big technological breakthrough, whatever it might be. This will ensure the company’s longevity for many years to come.