In our Annex 1 blog #4 we concluded that the key takeaway from the new ISO 14644-4 guidelines was the importance of science-based cleanroom design around the “surrounding” airflow patterns and contamination removal effectiveness, rather than a “rule of thumb” table of Air Change rates.

Right now, our challenge in GMP Cleanrooms is to move focus away from the air change rate table. Instead, we need to understand the science around contamination control and change our narrative from a table of Air Change Rates to air volume flow rates with new metrics of Air Change Effectiveness (ACE) and Contamination Removal Effectiveness (CRE).

Effective airflow design, verified through airflow visualization studies and local airborne particle counts in cleanroom grades without unidirectional air flow (UDAF), promotes:

- Improved behaviour

- Enhanced cleaning and disinfection practices

Confirmation of these benefits should be obtained through traditional viable Environmental Monitoring (EM) data.

Importance of Reassessing Air Change Rate Tables

It’s probable that the Air Change Rate table has been quoted and misused for over 2 decades. To enhance energy efficiency without compromising product quality or patient well-being, it is advisable to implement best practices outlined in ISO 14644-4 and -16 within the context of the new Annex 1. By leveraging the clauses in Annex 1, users can address routine compliance challenges while simultaneously decreasing air volume flow rates, contributing to a more sustainable and efficient system.

The airborne concentration in a non-UDAF cleanroom is determined by the airflow patterns created by the dilution of HEPA filtered air with room air and varies considerably depending on the emission rates from the people, activities, the process, and material movements. The air change rate, which is the total air volume flow rate divided by room volume, is purely a mathematical formula. Therefore this simplistic formula should not be used as the starting point in the design of a cleanroom. This can lead to higher airborne concentrations than expected in small rooms. It can also lead to lower airborne concentrations than necessary in larger rooms, with associated high capital and energy costs.

Contamination Control Strategy in HVAC Design

A key element of the CCS (Contamination Control Strategy), required by the new Annex 1 is to understand the process, the hazards and impact of possible contamination, and then design the airflow patterns around the Cleanroom, the processes, and activities, for effective contamination removal, i.e. the HVAC design.

The good news is that this is a particular area of Ardmac’s technical expertise. We have advanced HVAC design tools, along with integrated BIM and CFD (Computational Fluid Dynamics). These tools, that were expensive in the past are now routinely used in an integrated cleanroom design approach. HVAC technology has moved forward significantly since the late 90’s when the original ISO 14644-4 was being developed.

If we go back to the traditional table of air change rates again; the air change rate metric should not be discarded, it is still a useful reference. The recommended approach in Cleanroom design and adherence to Good Engineering Practice (GEP) suggests that the air change rate is an outcome of effective design. It should be calculated after establishing the supply air volume flow rate, rather than being the initial consideration. The more precise term introduced in the recent ISO 14644-4 is Air Change Effectiveness (ACE)

Evolution and Application of ISO 14644-4:2022

The new ISO 14644-4:2002 recognises that cleanroom technology has matured since the standard was developed in the mid 1990’s, before the internet was freely available. As a result, the new standard is not a ‘cook book’, rather it contains the relevant “things to be considered” as best practice in cleanroom design. The new -ISO14644 Part 4 has an extensive bibliography as reference material for more detailed design guidance on HVAC, utilities, material, and component selection, etc.

The downside of the new ISO 14644-4:2022 is that we need to understand the process and the contamination risks to carry out an effective cleanroom design. We’re back again to QRM (Quality Risk Management) and a CCS (Contamination Control Strategy) in the new Annex 1.

When we apply the new ISO 14644-4:2022 standard in the context of the new Annex 1 then we design our GMP cleanroom, based on understanding the process(es) and risks to the product, with a focus on the user requirements and contamination removal effectiveness, considering energy efficiency (ISO 14644-16:2019). We apply the principles of QRM and develop a CCS taking into account the URS (User Requirements Specification) from Annex 15 (Q&V) and data integrity from Annex 11(DI), resulting in the most effective and efficient GMP Cleanroom design, all with a laser sharp focus on contamination removal effectiveness.

The new ISO 14644-4:2022 presents several different formulas for calculating the correct supply air volume flow rates based on the process and expected emissions rates from the activities, including people movements and interventions, equipment processes and material handling.

In addition, the new ISO 14644-4:2022 standard offers 2 types of ventilation effectiveness, called indices. These are Air Change Effectiveness (ACE), and Contamination Removal Effectiveness (CRE).

The measurement of ventilation effectiveness can be determined using particle generators and LSAPC air samplers to measure particle concentrations. ACE shows how much clean air a location receives, compared to the average in the cleanroom. An alternative ventilation effectiveness data contributor is the CRE number. This measures the effectiveness of the removal of particle contamination.

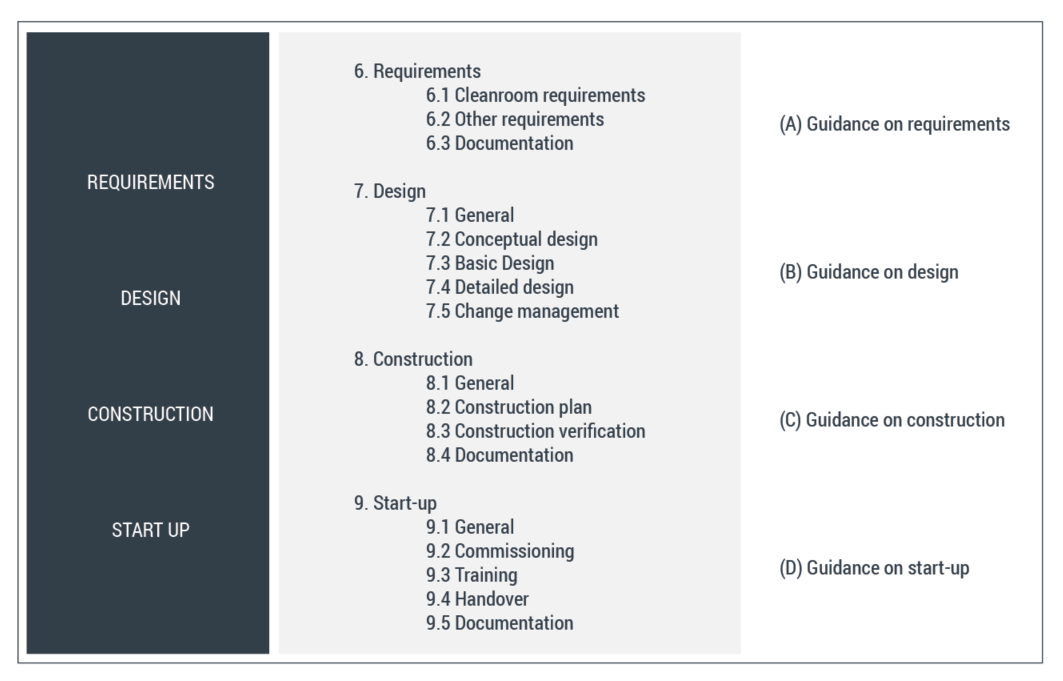

Summary of changes

A future blog will discuss the new ISO 14644-4:2002 and its application to GMP cleanrooms, but for a start, here is a summary of the changes from the 2001 version:

- Design, construction and start up FLOWCHART in a logical sequence

- Consideration of other cleanliness attributes and energy management

- Overhaul of informative annexes with alignment to Normative clauses

- Removal of potentially misleading and out-of-date information

- Expansion of the process for defining requirements and design stages

- Expansion of information relating to Clean Build protocols (was in ISO 14644-5:2004)

- Focus on effective air mixing and dilution for CRE

- Focus on airflow patterns and air change effectiveness (ACE) index

- No table of air change rates – replaced with ACE index based on GEP (Good Engineering Practice), experience, knowledge of the process and contamination control strategy, airflow patterns, and CFD (Computational Fluid Dynamics), if required

- The ACE index will give a measurement of local dilution and mixing effectiveness; 1 being the goal, but above 0.7 is considered acceptable

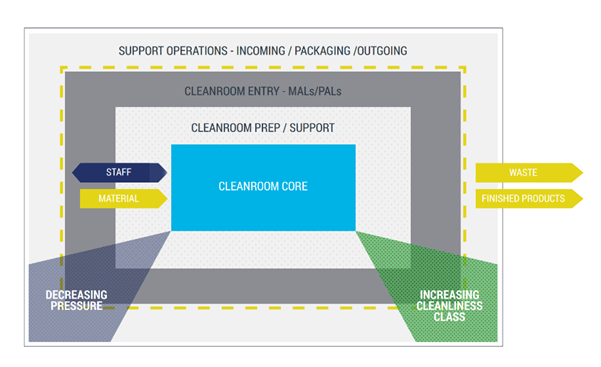

The updated standard still focusses on the “Onion” or “Box in a Box” concepts for segregation, separation, and containment of contamination.

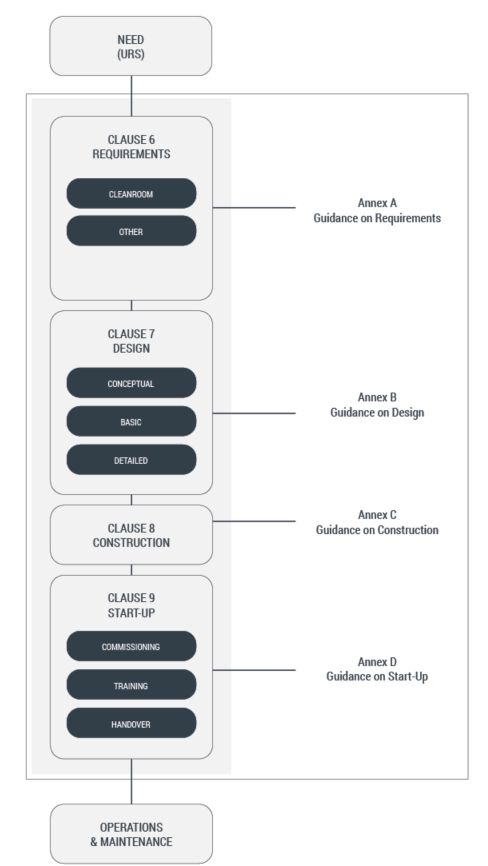

The new ISO 14644-4:2022 has a clear layout and logical flow:

Below is a flowchart. Good cleanroom design starts off with the URS from Annex 15 (Qualification and Validation)

A future blog will discuss the new ISO 14644-4:2022 standard in more detail and the link to Energy Management and Efficiency in cleanrooms (ISO 14644-16:2019).