Clas-Sic Lochgelly

Clas-Sic Wafer Fab

Client: Clas-Sic

Location: Lochgelly, Scotland

Project Size: Approx. 680m2

Duration: 8 Months

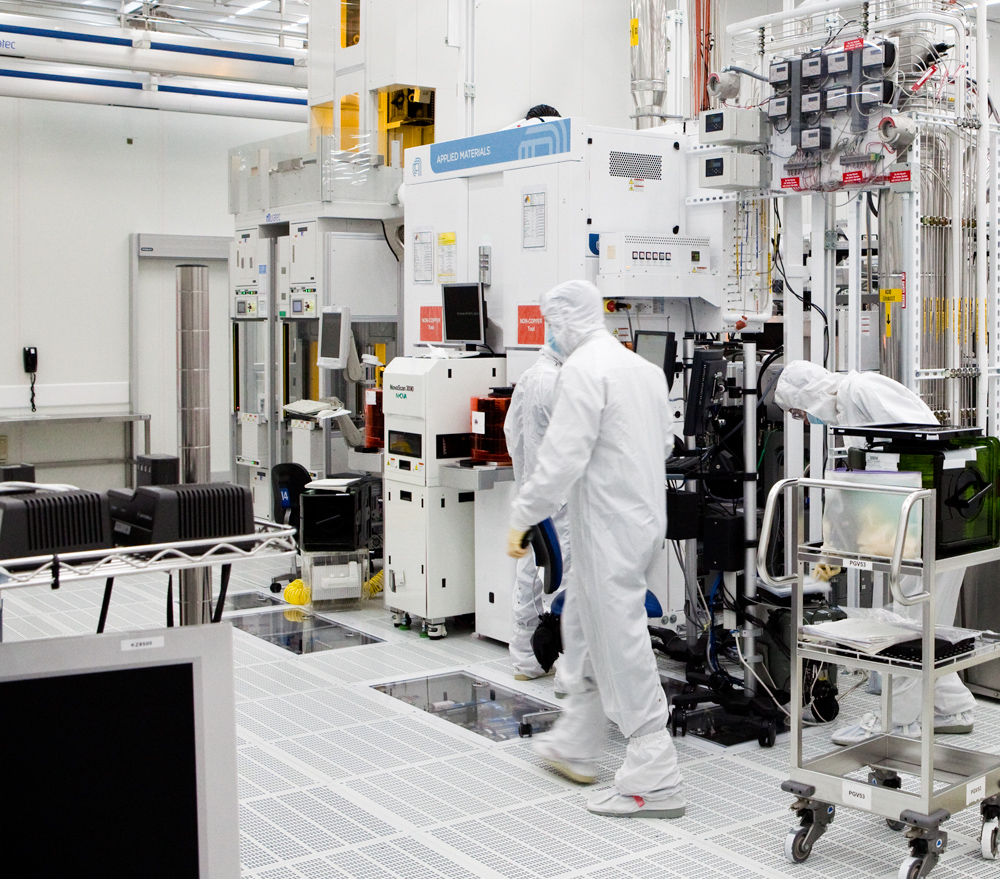

The Lochgelly package consisted of the supply, installation and commissioning of the cleanroom systems at a new semi-conductor type cleanroom, occupying Units 10 and 12 (existing) and the new building extension. Ardmac provided ‘as fitted’ drawings and O&M manuals for all systems modified and / or installed.

The scope of works included:

- Preparation of building shell – Final preparation and finishing of all soffits walls and floors within the areas used for the cleanroom and supporting plant not already covered.

- Structure – Self-contained lightweight structure fixed to existing steelwork to support cooling coils, ceiling plenums and walls.

- Flooring – Electro-dissipative vinyl (supplied and fitted by others).

- Ceiling – Install 50mm gasketed ceiling grid housing Fan Filter Units, tear drop lights and blank panels. Ceiling in clean support areas is positive plenum with lay in blank pans and low profile ULPA filters.

- Walls – Cleanroom perimeter walls based upon 100mm thick modular construction and internal walls based on 65mm thick monobloc construction.

- Doors – Semiconductor – Side hung egress doors between cleanroom and corridor areas, glazed. Stainless steel ironmongery.

- Signage – Modular aluminum wall mounted room signage for means of escape and room description.

- Sensible Cooling Coils – Installation of Coils within ceiling areas between clean bay and chase.

- Fan Filter Units – EC driven fans with U15 filters mounted in dry gasketed grid.

- Lighting – Cleanroom lighting, including tear drops and suspended fittings with gold sleeves for photo area.

- Emergency Lighting – Utilise self- contained emergency fittings.

Key Aspects:

Production Area – ISO 6 and ISO 5, gowning – ISO 6, pre-gowning – ISO 6, clean support – ISO 6 cleanroom walls, plenums, ceilings, lighting, doors & vision panels, FFUs, ULPA filters etc.